Project Description:

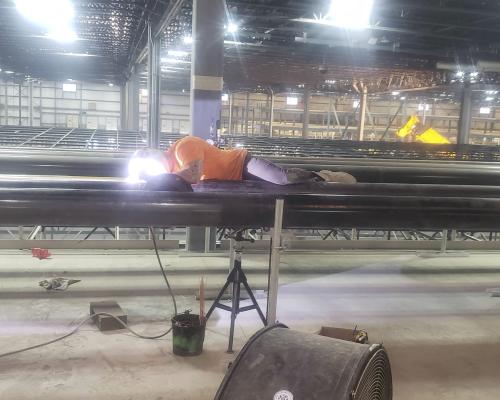

Midlands Mechanical was selected to provide full mechanical support for the conversion of an existing 535,000 sq ft warehouse into a new state-of-the-art manufacturing facility for Hormel Foods. Our team installed nearly every mechanical system in the building — including underground piping, utility connections, and process systems across the entire plant.

From day one, the project required aggressive coordination, tight timelines, and precision installation. We handled everything from boiler systems to nitrogen and hydraulic process piping — along with hundreds of utility drops, fixtures, and drains throughout the facility.

Scope of Work:

- Underground drain, waste, and vent systems

- Process piping: steam, condensate, nitrogen, hydraulic, compressed air

- Domestic water and sanitary sewer

- Air compressors, dryers, and complete utility air system

- Boiler installation and support piping

- Reverse osmosis water system and high-purity supply lines

- Hose stations, sinks, eye wash stations, and utility drops throughout

- Full mechanical infrastructure for new manufacturing layout

- Shutdown support, tie-ins, and production equipment hook-ups

Client Note:

This was a fast-paced conversion project with major mechanical complexity. We were trusted to install it all — and did so under tight scheduling and coordination alongside multiple trades.