Project Description:

Midlands Mechanical was contracted by Adolfson & Peterson Construction to provide the complete mechanical package for the NW Berthoud Campus Expansion – Phase 1, located at 220 Water Avenue in Berthoud, Colorado.

This project supports Northern Colorado Water Conservancy District’s expansion of its operations campus. Work required installing new heating, cooling, and mechanical distribution systems for multiple new and renovated buildings included in Phase 1. The subcontract totaled $260,000, covering installation of all HVAC/mechanical components specified in Exhibit D.

The project involved coordinating with AP Mountain States, RB+B Architects, and other trades under a multi-building construction schedule extending from 2021 into 2022. All work was required to follow strict quality control, schedule sequencing, and documentation practices, including mandated submittals, testing, inspections, safety compliance, and coordinated scheduling.

Scope of Work & Responsibilities:

Mechanical System Installation

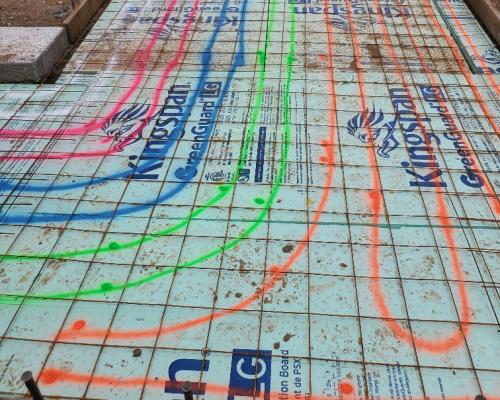

According to the subcontract and scope exhibits, Midlands Mechanical was responsible for providing all labor, materials, equipment, supervision, and tools necessary to perform the mechanical scope for the NW Berthoud Campus Expansion Phase 1. This included:

- Complete mechanical installation (HVAC, heating, cooling, and related systems).

- Providing all shop drawings, product data, samples, submittals, and the mechanical specification sections.

- Furnishing all equipment, materials, piping, insulation, supports, and accessories necessary for a fully operational mechanical system.

- Providing all tests, permits, inspections, and commissioning tasks associated with mechanical completion.

Project Coordination & Administrative Requirements

Project requirements mandated that Midlands Mechanical must:

- Attend weekly coordination meetings with the general contractor and other trades.

- Provide detailed coordination drawings and participate in BIM/VDC processes as needed.

- MMI Quality Assurance Plan

- Submit and maintain a project schedule tied directly to milestones for mechanical installation.

- Provide a Schedule of Values, monthly invoicing through Textura, lien waivers, billing backup, and documentation of stored materials.

- Manage all deliveries, staging logistics, and installation planning with AP Mountain States.

Quality Assurance & Testing

Using Midlands Mechanical’s internal QA Plan, the following responsibilities were included:

- Weekly site visits by the Project Manager to verify installation progress and identify deficiencies.

- Maintaining an Issues Log, Equipment Delivery Log, and Submittal Log.

- Executing all functional testing and system test reporting per specifications.

- Preparing and submitting O&M manuals, training, and as-built documentation.

- MMI Quality Assurance Plan

Compliance, Safety & Documentation

The subcontract required strict compliance with:

- AP’s safety program and all OSHA regulations.

- All building codes and inspection requirements.

- Insurance, bonding, and additional-insured requirements as exhibited in the COI you provided.

- Site rules including clean-up, parking, material handling, and subcontractor coordination.

Client Note:

This project required close coordination with multiple design stakeholders across several buildings in the campus expansion. Midlands Mechanical provided complete mechanical construction support including submittals, scheduling, QA documentation, and system testing while working alongside other trades in a dense, multi-phase construction environment.

Through consistent communication, proactive planning, and a strong quality control program, Midlands Mechanical delivered a reliable mechanical installation that supports the Northern Colorado Water Conservancy District’s long-term operational needs for its growing Berthoud campus.