Project Description:

NSK Clarinda manufactures precision bearing components in a large-scale, high-output facility. Midlands Mechanical has been a long-time on-site contractor, supporting the plant for decades with mechanical upgrades, shutdown work, and process improvements across nearly every part of the facility.

Our work includes utility changes, equipment tie-ins, high-pressure piping, nitrogen lines, filter systems, and structural work. Projects range from emergency service to phased capital improvements — often performed under tight production constraints or holiday shutdowns.

Scope of Work & Responsibilities:

Our work at NSK includes:

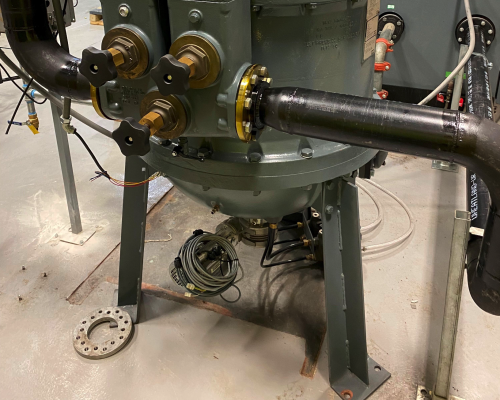

- Installation and rerouting of process piping

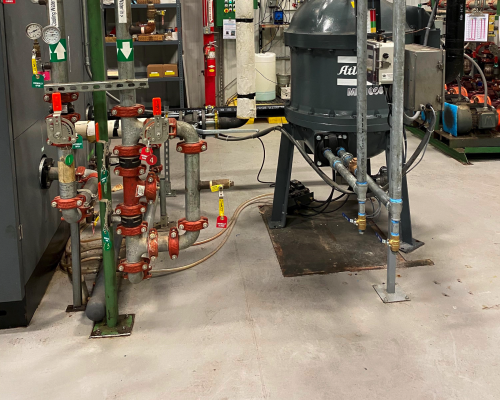

- Compressed air system upgrades and header modifications

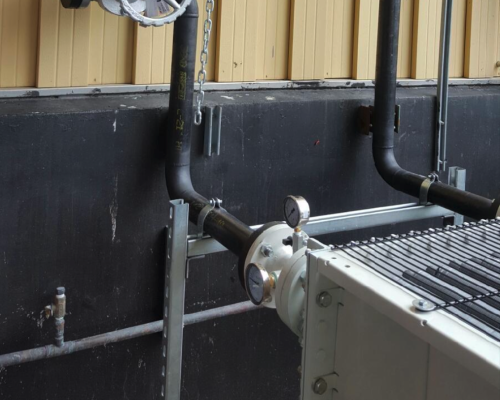

- Cooling water lines for heat treat equipment and air dryers

- Nitrogen and hot oil piping in heat treat areas

- Cooling tower piping replacement

- Quench oil piping

- Filter system replacements and bag filter relocations

- Pump replacements and leak repairs

- Piping modifications for furnaces, washers, and gas systems

- Structural steel repairs

- Valve installs and utility isolations

- Full shutdown coordination and emergency service support

Client Note:

This is a long-standing client who counts on us to work efficiently and safely. We know the site, the systems, and the people — and we’re trusted to step in and handle whatever mechanical work comes next.